Graphene which has a high dispersibility in various solvents without a dispersion agent Hi-puri & Hydra.

(Chemical peeling + physical peeling)

UD (UDerive) corporation has developed the hybrid graphene as a hybrid method that combines the chemical and mechanical methods in the exfoliation section and hydrotreatment and high-temperature treatment in the reduction process and named Hi-puri and Hydra.

They are graphene with excellent performance and have the freedom to disperse in most solvents by allowing energetic self-assembly through hydrotreatment to be free from surface energy.

They are graphene with excellent performance and have the freedom to disperse in most solvents by allowing energetic self-assembly through hydrotreatment to be free from surface energy.

Close

Graphene which has a high dispersibility in various solvents without a dispersion agent Hi-puri & Hydra.

CNT and graphene have been applied as materials for improving properties such as mechanical strength/flexibility and strong chemical/heat resistance.

However, they were difficult to disperse at the time of application, so a dispersant had to be used, which made it difficult to obtain expected physical properties and to achieve uniform quality.

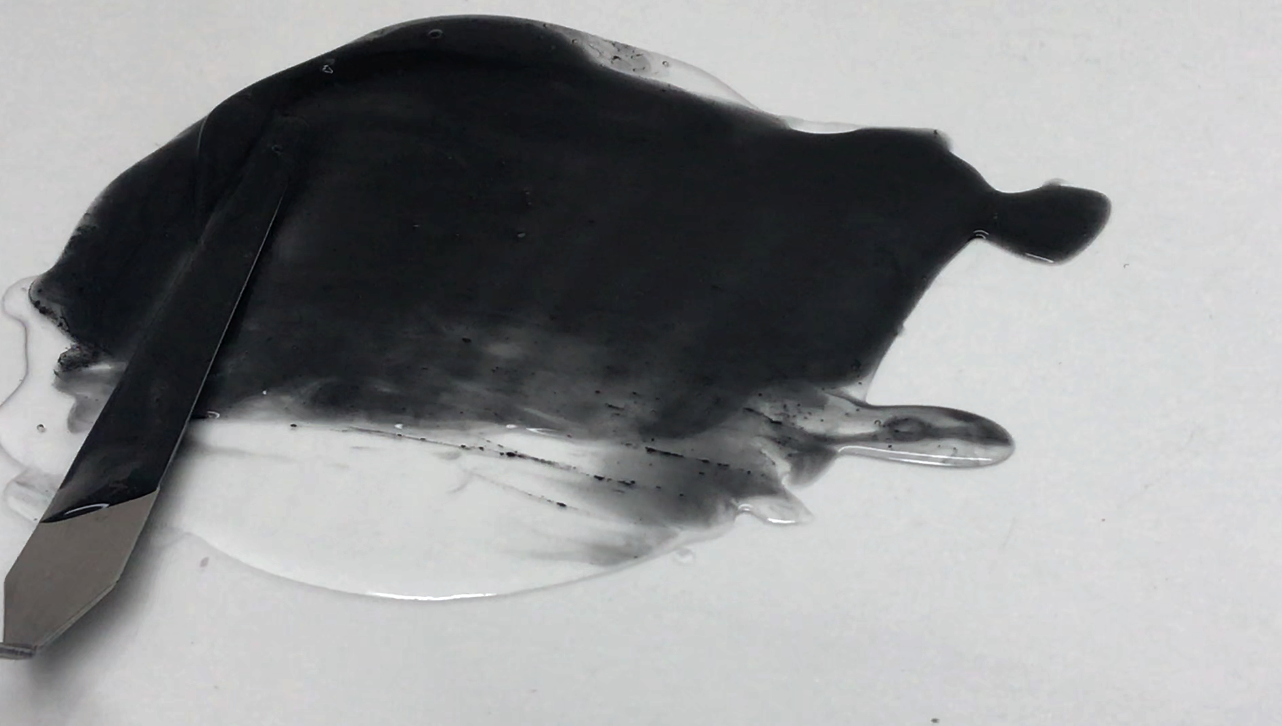

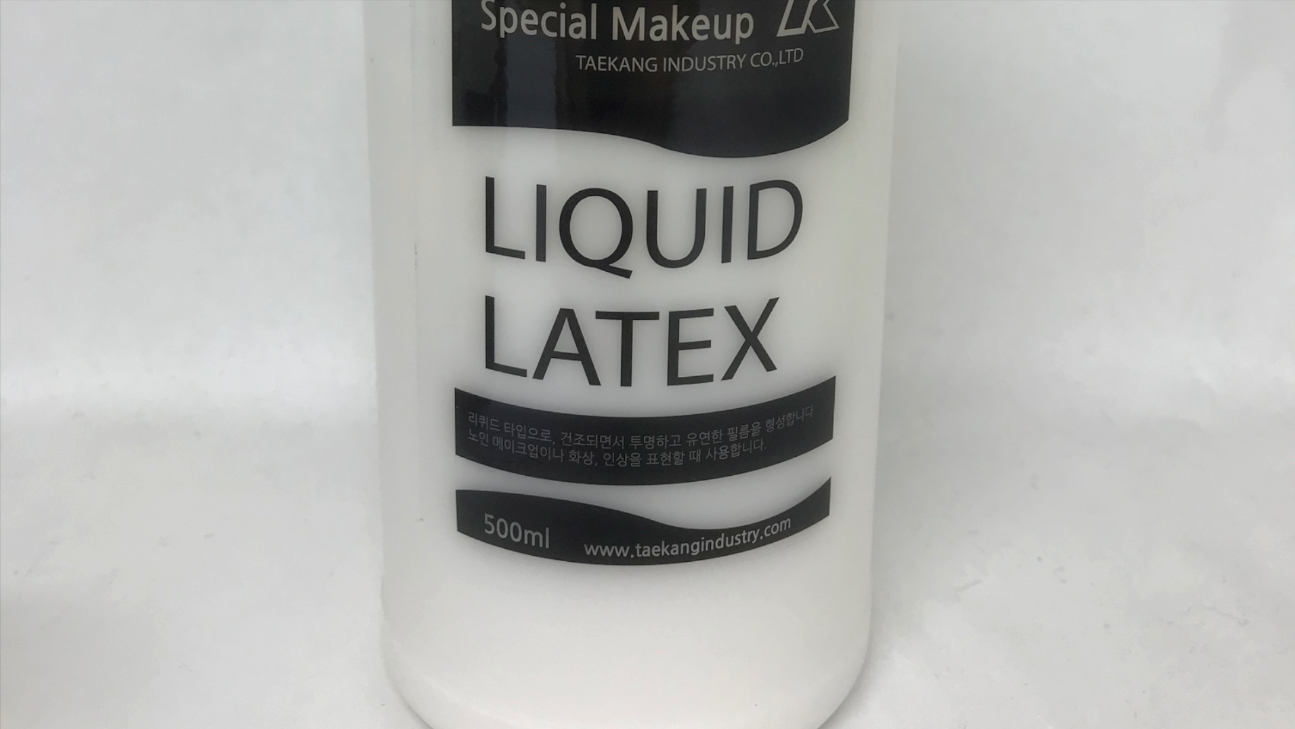

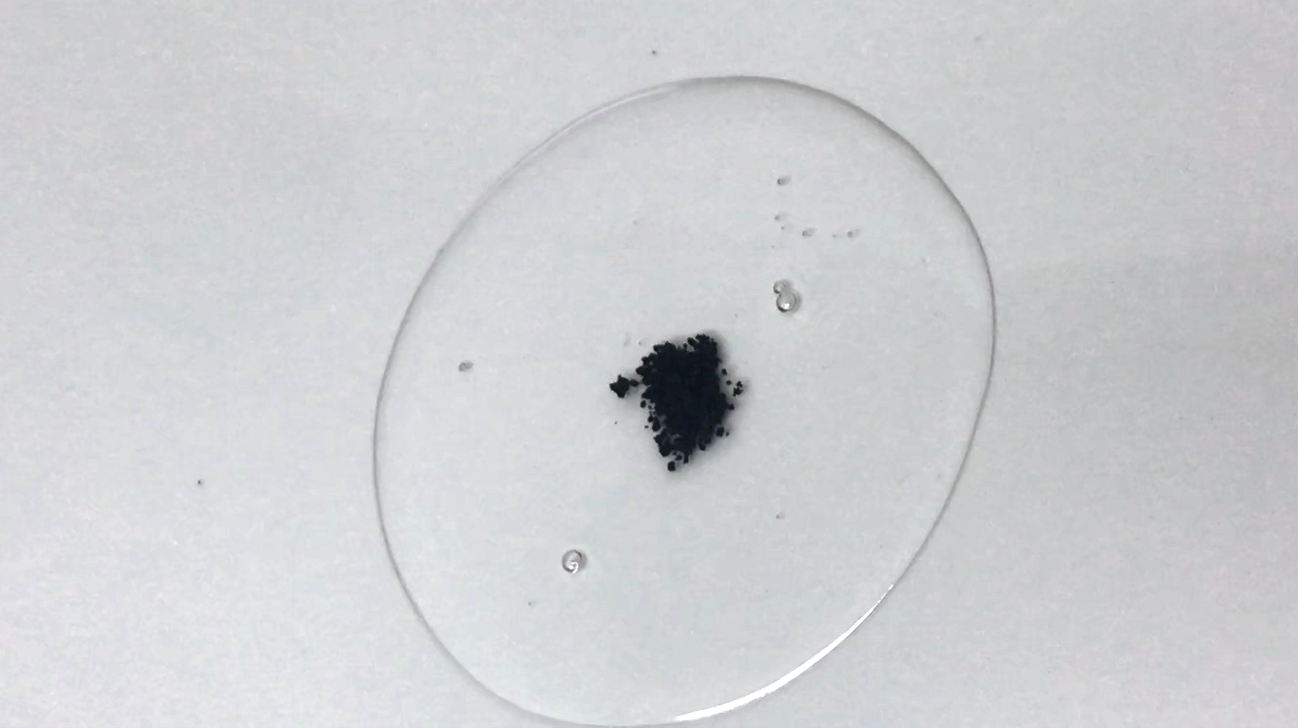

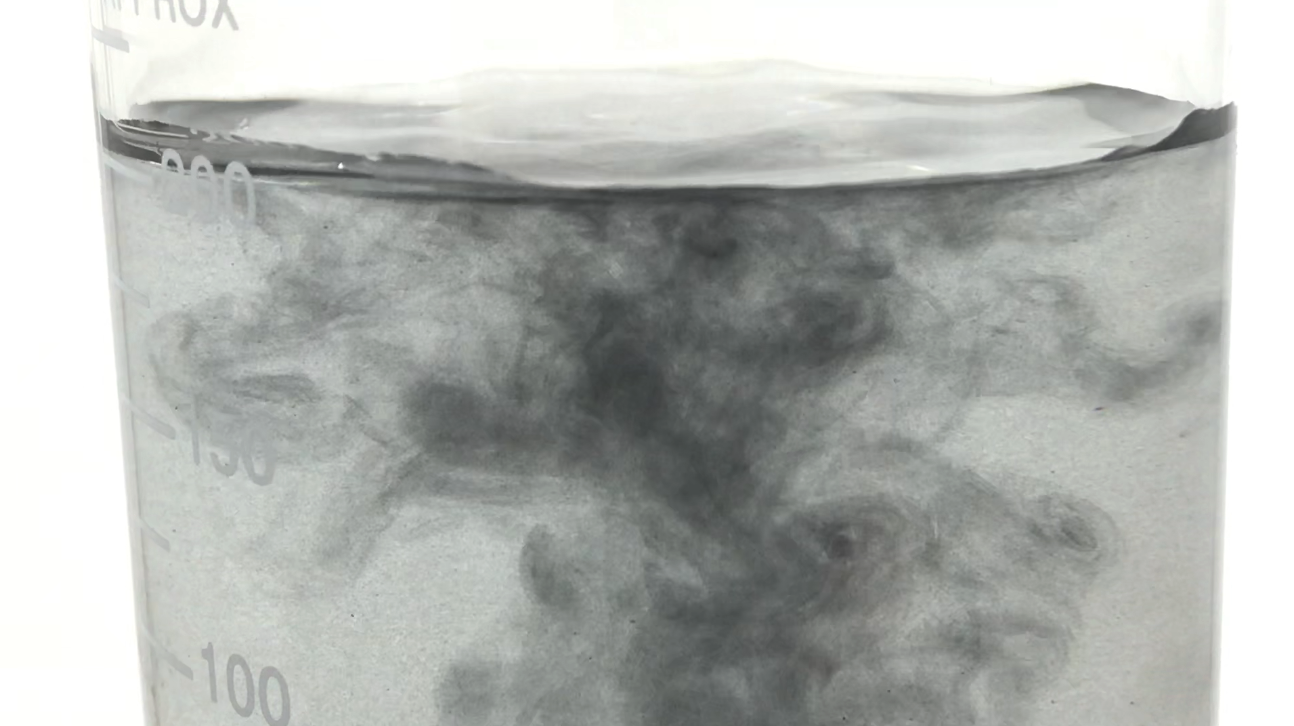

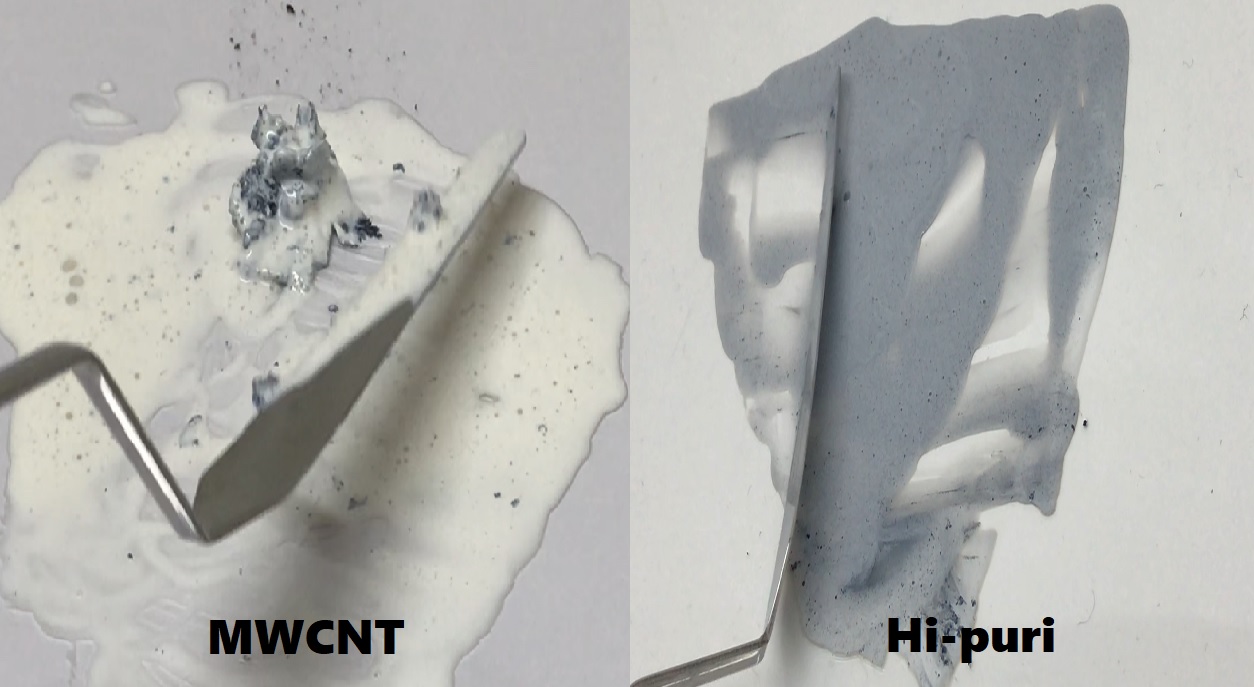

As a typical example, MWCNT and Graphene were not mixed with liquid latex.

It was difficult to apply because it lumped itself together and was not completely dispersed.

If graphene mixes well without a dispersion agent, the necessary properties can be expected through bonding with a variety of solvents (water, paint, latex, epoxy, polyurethane, silicone, etc.) necessary for the coating, plastic and elastomer industries.

Besides, graphene can be viewed as an additive or function enhancer.

To do this, graphene must be well mixed in the solvent without additional additives.

It was difficult to apply because it lumped itself together and was not completely dispersed.

If graphene mixes well without a dispersion agent, the necessary properties can be expected through bonding with a variety of solvents (water, paint, latex, epoxy, polyurethane, silicone, etc.) necessary for the coating, plastic and elastomer industries.

Besides, graphene can be viewed as an additive or function enhancer.

To do this, graphene must be well mixed in the solvent without additional additives.

Conventionally, graphene can be divided into oxidized and reduced graphene.

Graphene oxide has strong dispersibility. Still, due to low electrical conductivity and low thermal conductivity, it was difficult to expect improvement in

properties only by adding graphene.

Reduced graphene has high electrical conductivity and high thermal conductivity, but it is difficult to apply due to low dispersibility.

Although functionalized graphene is coming out, it is only modified according to each solvent, and it is also necessary to stir a lot of time for dispersion.

Graphene oxide has strong dispersibility. Still, due to low electrical conductivity and low thermal conductivity, it was difficult to expect improvement in

properties only by adding graphene.

Reduced graphene has high electrical conductivity and high thermal conductivity, but it is difficult to apply due to low dispersibility.

Although functionalized graphene is coming out, it is only modified according to each solvent, and it is also necessary to stir a lot of time for dispersion.

UD (UDerive) corporation has developed the hybrid graphene as a

hybrid method that combines the chemical and mechanical methods

in the exfoliation section and hydrotreatment and high-temperature

treatment in the reduction process and named Hi-puri and Hydra.

They are graphene with excellent performance and have the freedom to disperse in most

solvents by allowing energetic self-assembly through

hydrotreatment to be free from surface energy.

hybrid method that combines the chemical and mechanical methods

in the exfoliation section and hydrotreatment and high-temperature

treatment in the reduction process and named Hi-puri and Hydra.

They are graphene with excellent performance and have the freedom to disperse in most

solvents by allowing energetic self-assembly through

hydrotreatment to be free from surface energy.

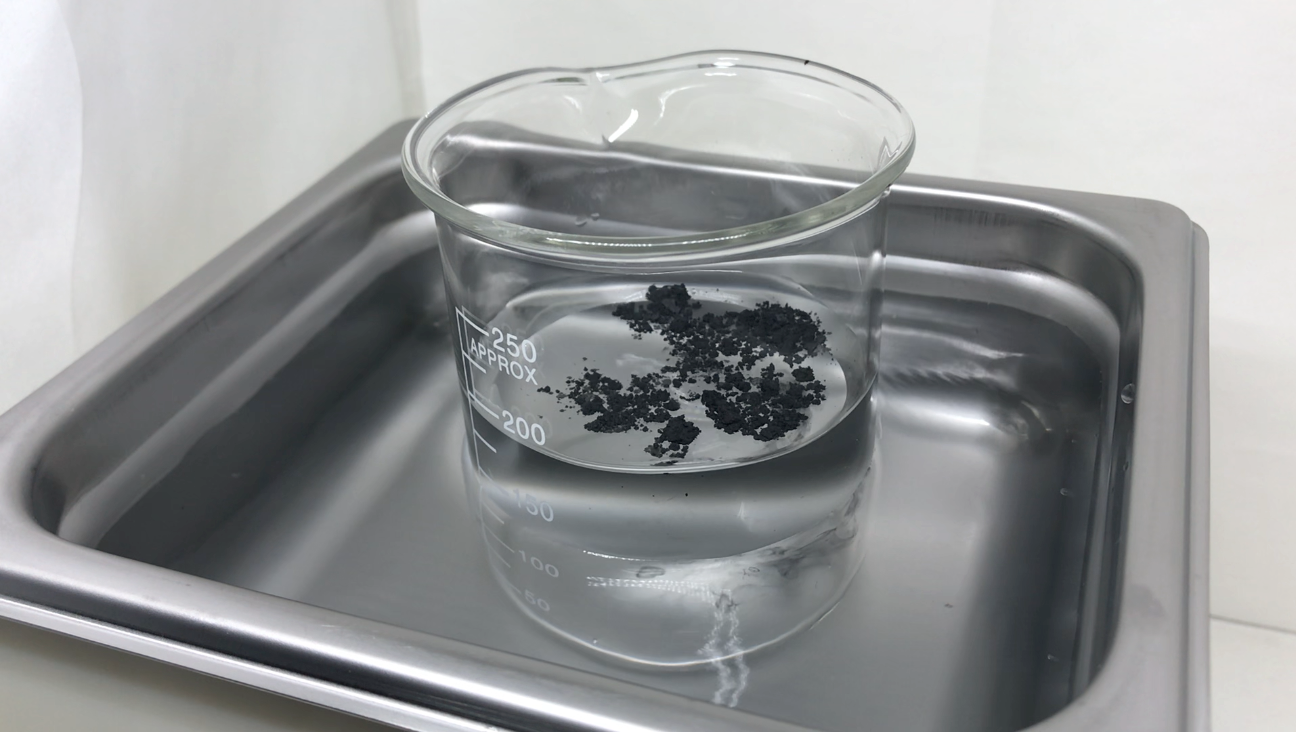

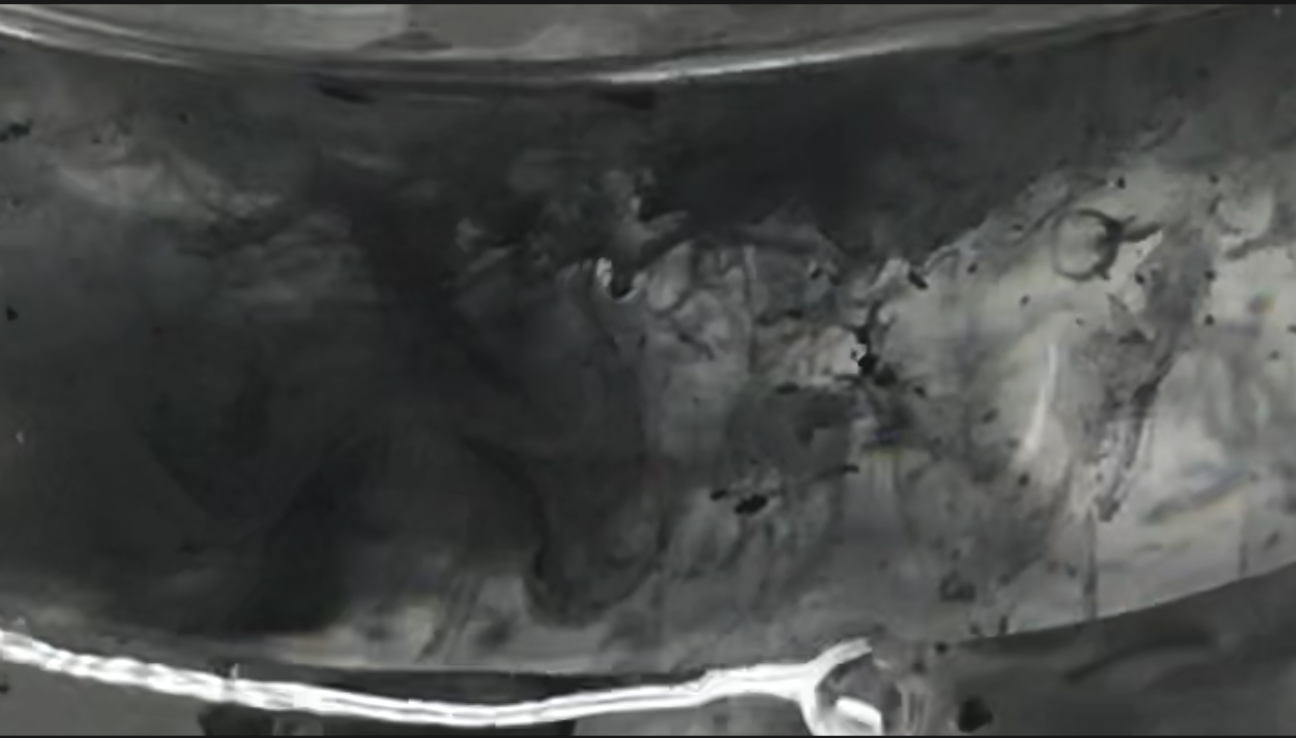

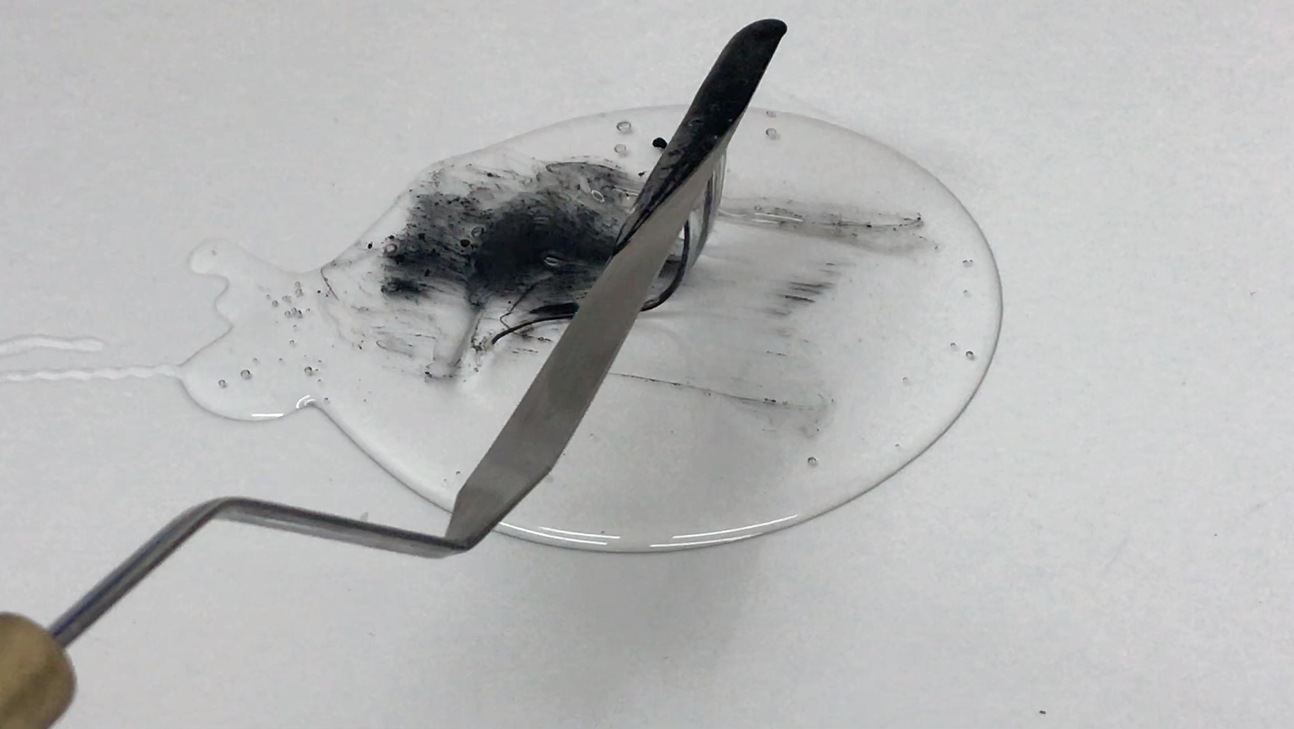

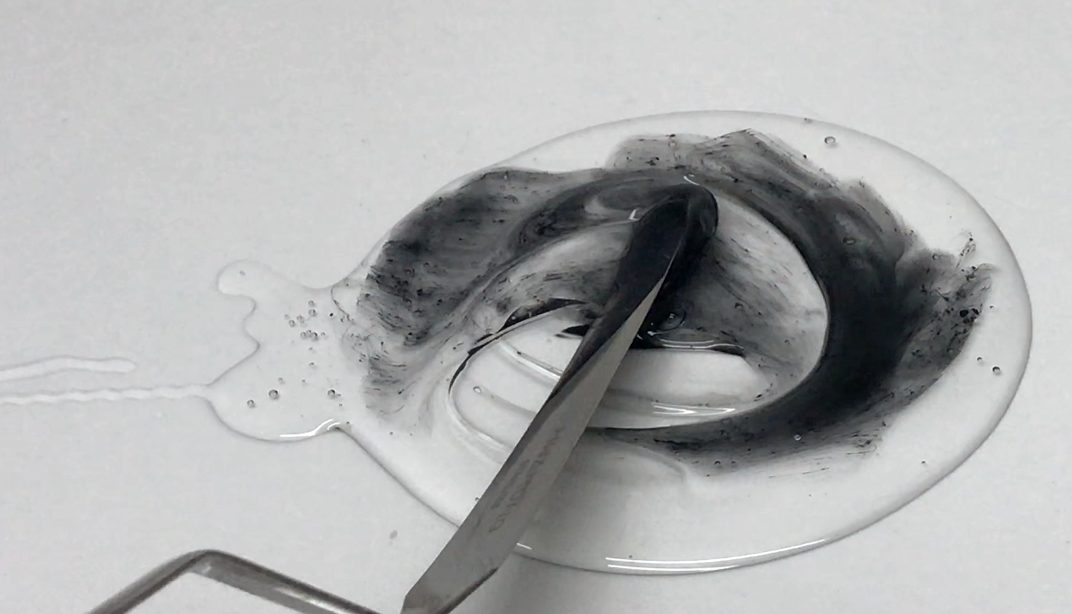

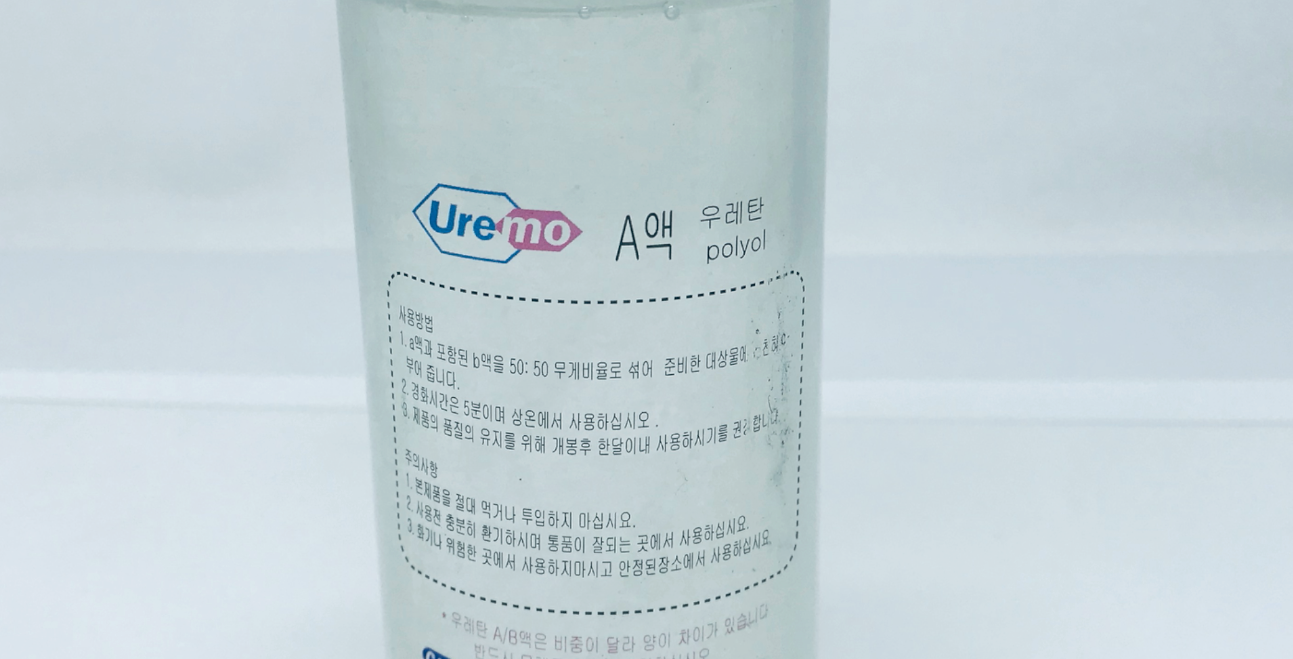

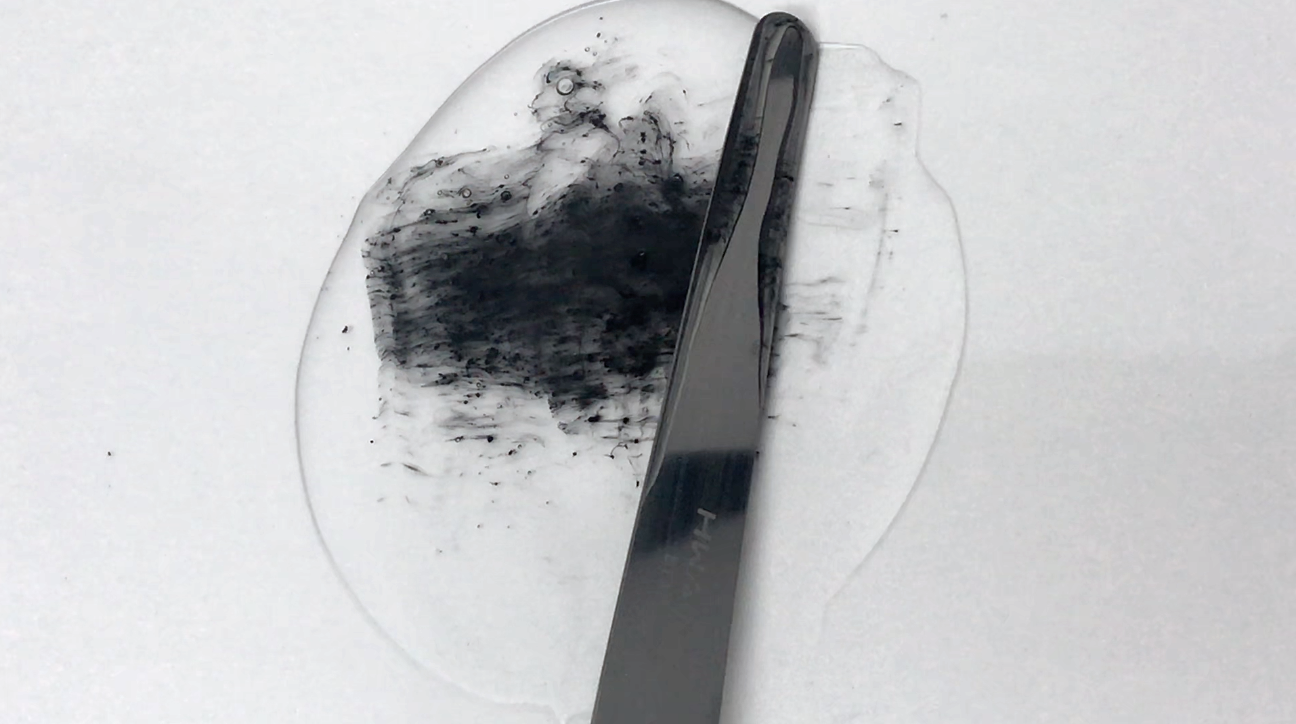

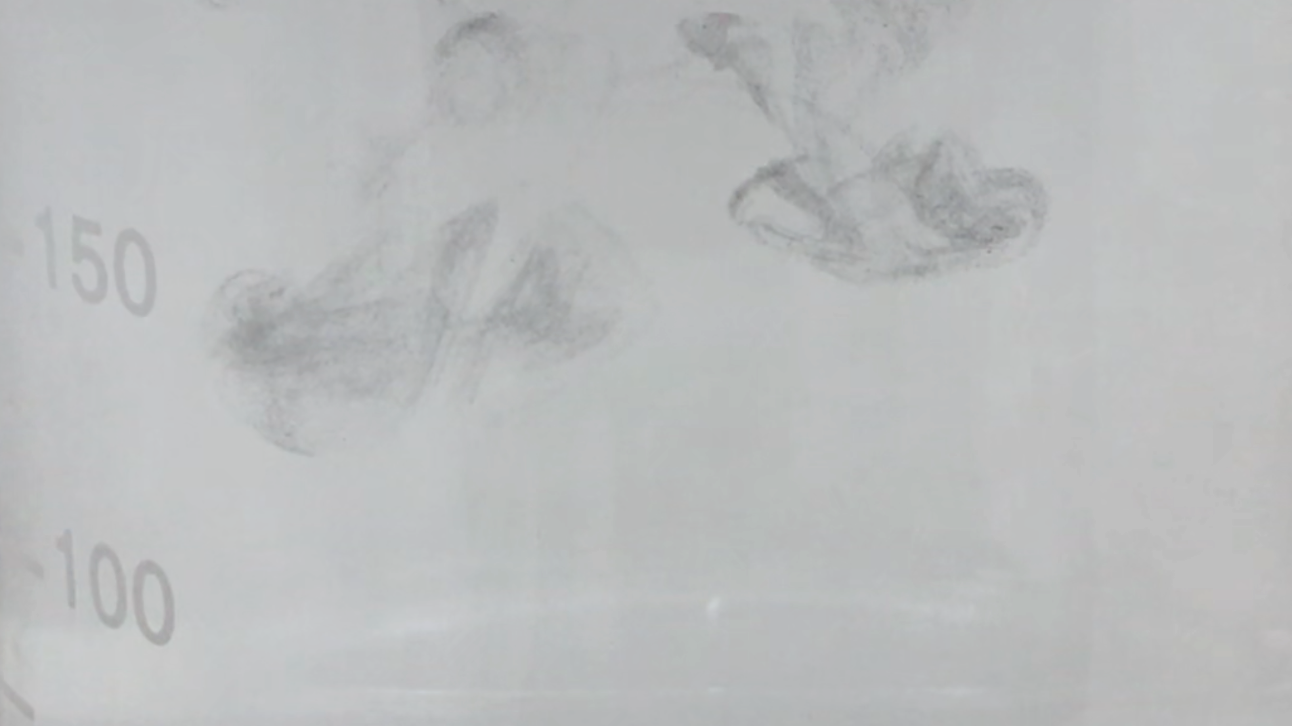

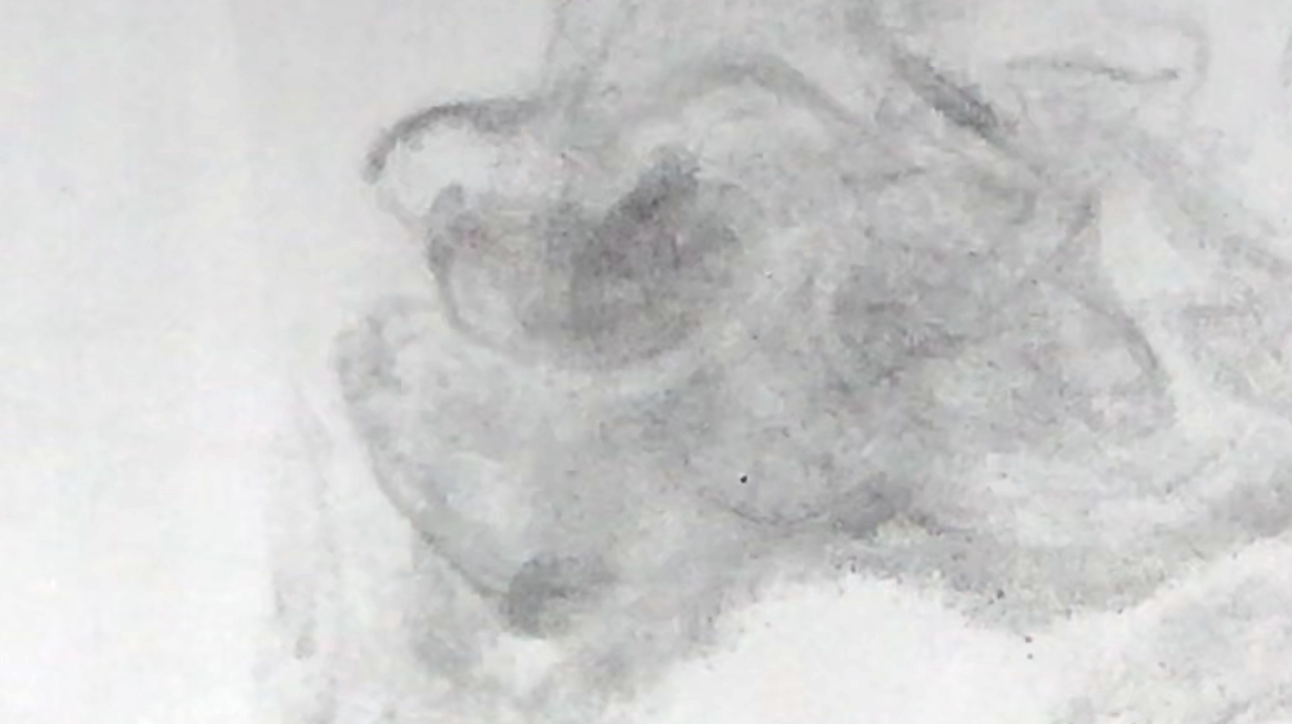

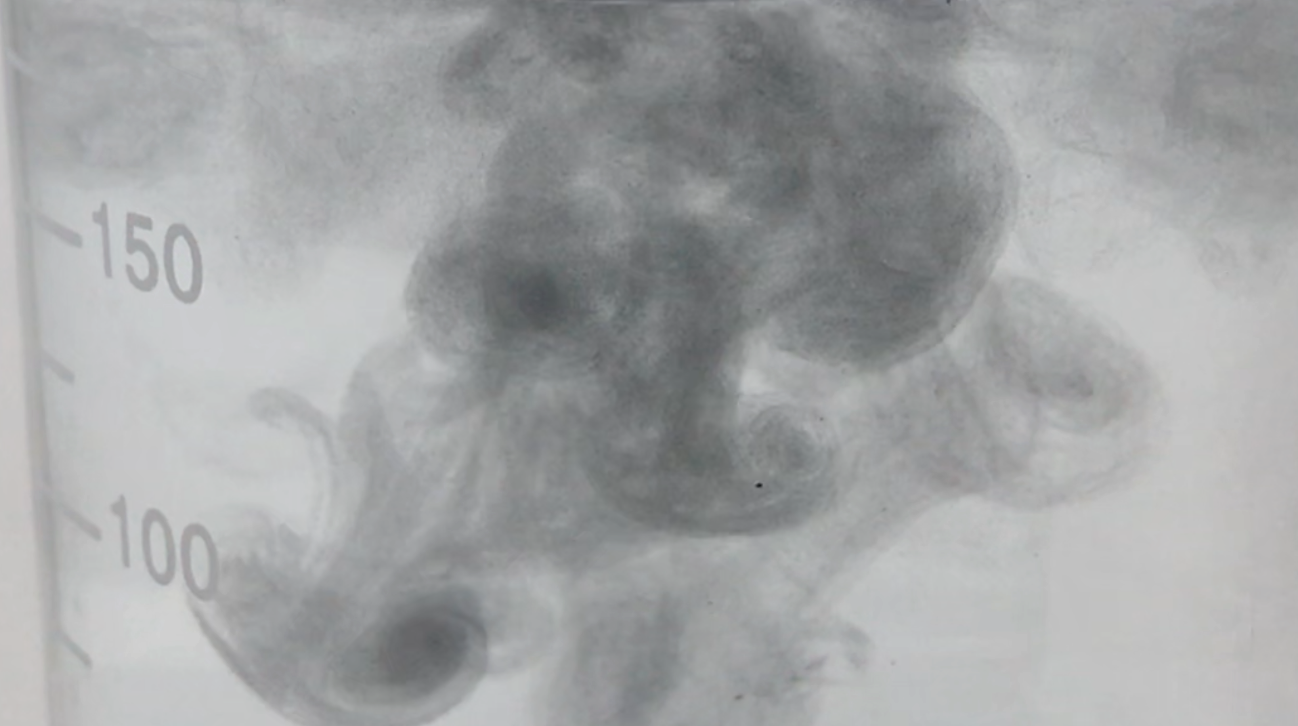

As we can see in the video and pictures under, The Hi-puri and Hydra are well dispersed in water, paints, liquid latex, epoxy resin, PU and silicone elastomer without special tools and additives or dispersion agent.

Also, you can check the improvement of basic properties and applicability from UD paints, pastes and inks applied with Hi-puri.

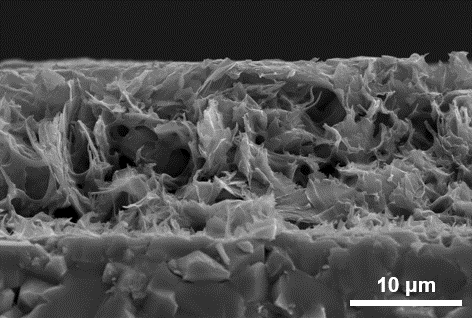

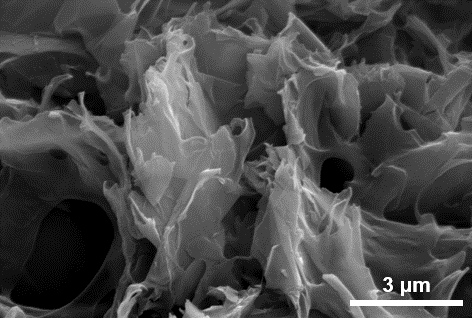

You can see that graphene is evenly dispersed and coated on the fracture surface of the plate coated with UD's conductive ink Hicon-V.

UD's Hybrid Graphene can be used as an additive to improve it`s function. Even in electroplating, the properties of the plating layer can be changed by adding a very small amount of Hi-puri.

UD's hybrid graphene has overcome the limitations of normal graphene, and at the same time, has formed high mass production and a reasonable price.

Also, you can check the improvement of basic properties and applicability from UD paints, pastes and inks applied with Hi-puri.

You can see that graphene is evenly dispersed and coated on the fracture surface of the plate coated with UD's conductive ink Hicon-V.

UD's Hybrid Graphene can be used as an additive to improve it`s function. Even in electroplating, the properties of the plating layer can be changed by adding a very small amount of Hi-puri.

UD's hybrid graphene has overcome the limitations of normal graphene, and at the same time, has formed high mass production and a reasonable price.

Dispersibility

The Hi-puri and Hydra are well dispersed in water, paints, liquid latex, epoxy resin, PU/Polyurethane resin and silicone elastomer without special tools and additives or dispersion agent.

Product